Three Ways to Bring Wind O&M in-House With Ease

Energy organizations are seeing the extensive value that self-performing operations and maintenance can have on their bottom line.

From reducing downtime to improving productivity and overall ROI, this trend is clear: While the market has traditionally been led by OEMs providing these services, OEMs are beginning to lose market share in O&M due to a push from leading asset operators for more flexible service arrangements.

According to Wood Mackenzie, while O&M spend varies considerably per MW, per market, the annual operations and maintenance spend will hit $25billion by 2029.

In 2021 and beyond, as the renewable energy sector becomes increasingly competitive, seasoned asset owners are demanding a more active role in their O&M strategy. Providing benefits in asset performance, safety, and productivity, this approach also gives the power directly back to operational owners by harnessing engineers’ knowledge and the site’s history.

HOW DO WE GET STARTED?

The most integral component to moving to self-performing maintenance is the operation of a fault response system, that is, the maintaining and deploying of a database of corrective actions against particular turbine fault codes or insights from analysis.

Below, we’ll walk you through three steps for building, maintaining, and deploying this system in the most efficient way. Then, we’ll cover how a wind farm owner transitioned to a self-performing model on their wind farms.

THREE TIPS FOR TRANSITIONING TO SELF- PERFORMING O&M :

1 Deploy Automation Logic

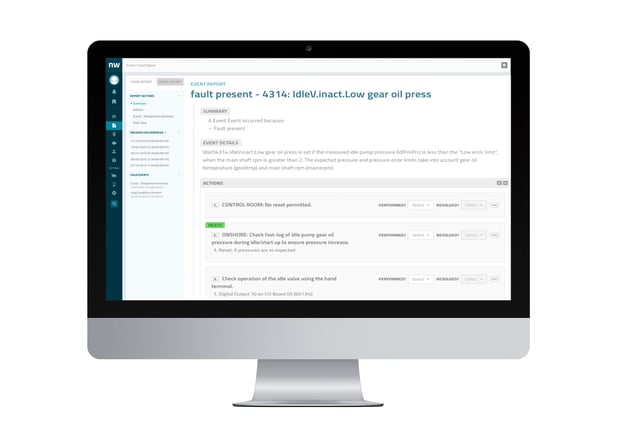

The first crucial step towards moving to self-performing maintenance is the ability to respond to turbine faults as quickly as possible - which means processing, analysing and displaying data in real-time.

When dealing specifically with turbine alarms, this means deploying some automated logic that groups hundreds of wind turbine alarms into a few manageable events.

For SCADA data, on the other hand, this means deploying analyses that result in an interactive event.

Either way, the key here is to automate whatever you can but provide the functionality so the manual intervention is as easy as possible.

2 Prescribe Corrective Actions

The next step is the ability to present these events (grouped alarms or insights from data) alongside the appropriate corrective actions. The appropriate actions should be called whenever an event and displayed alongside interesting information about which actions have been successful in the past.

These actions should always be improving, so we recommend making it easy to edit actions, add notes, reorder them, and then save them for the next time that same event occurs.

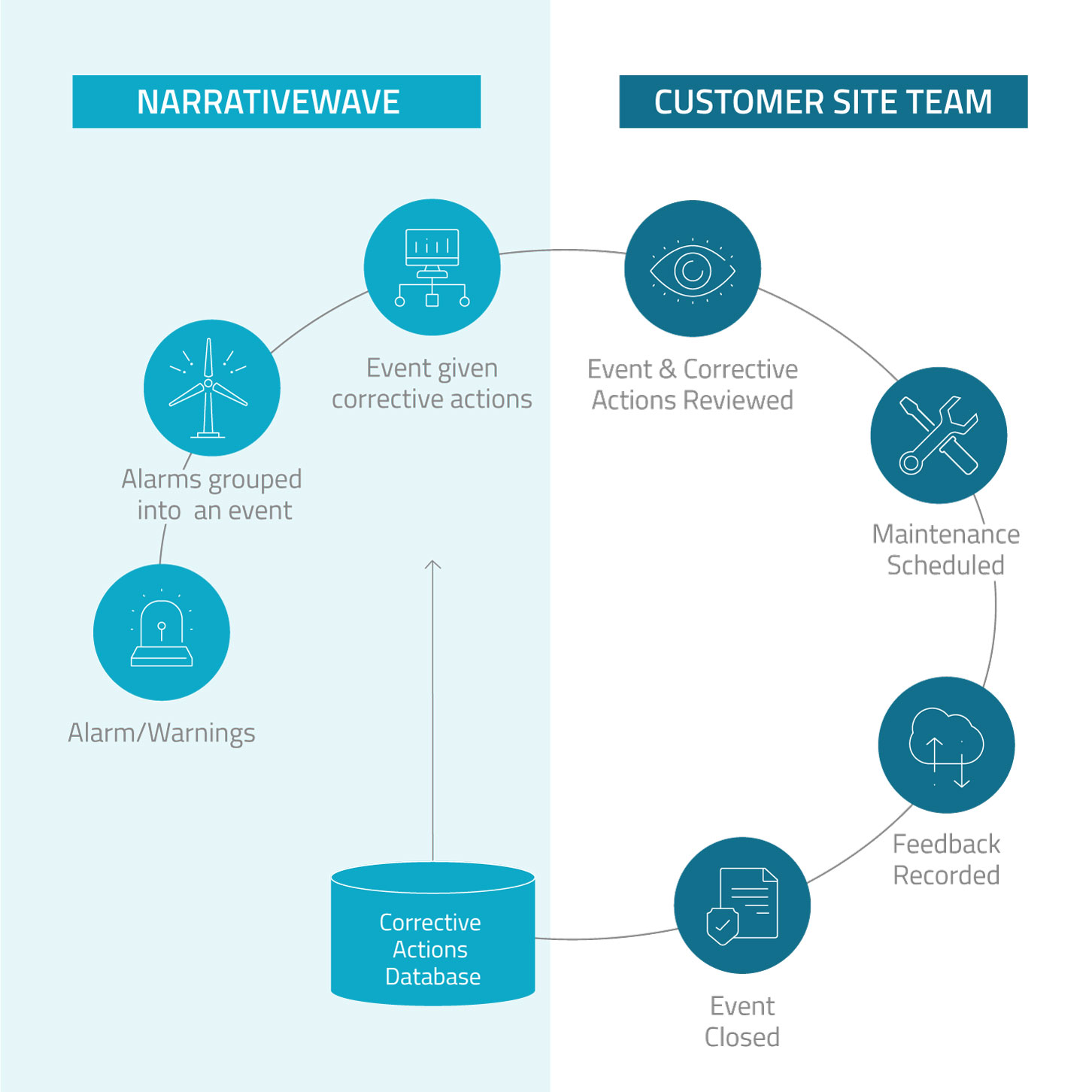

3 Enable a Feedback Loop

Finally, make it as easy as possible for your turbine experts to record their feedback. Specifically, users should be able to record both structured feedback (E.g. “This action worked”), and unstructured feedback such as comments.

To ensure maximum value and usefulness, the system must also make it easy to use the feedback to improve both the knowledge base of corrective actions, as well as the recommendations for this action and parts to utilize first. This can combine manual methods of ranking actions, as well as an automated feedback system that scores actions.

Ideally, this is a continuous loop enabled through seamless communication at each level of your operations, engineering, and site teams.

Above is an ideal communication loop. Each of the steps above should be familiar to any O&M provider, although there will be those who suggest they have this process ‘completely covered’ in some shape or form already; the piece that is often missing is the joining of each individual step in the most efficient, organized and user-friendly way possible.

Real-World Results

RWE, a top global renewable energy operator, partnered with NarrativeWave to facilitate their new O&M procedures after transitioning to self-performing maintenance.

Rather than just reacting to alarms, RWE needed to use a system to get the correct fix, the first time, and standardize fault responses.

Automated Corrective Actions

Since implementing NarrativeWave, RWE has seen the following improvements:

- Automated Standardized Responses - this significantly reduced the time needed to analyze faults, determine the best corrective action, and respond.

- Real-time field Feedback - allowed for critical insight directly from the field in both structured and unstructured formats.

- Simplified Operations - focusing on the most probable corrective actions - rather than leaving it to site technicians to troubleshoot themselves.

- Improved Supply Chain Communication - providing knowledge into why a turbine was faulting means better communication about what parts and inventory are needed over time.

- More Prepared - operators can bring the right parts and tools to the turbine- this reduces costs, complexity, and repeat visits.

- Lasting Knowledge - with the NarrativeWave software, knowledge is captured both upfront and over time, consistently improving operations.